High voltage solutions for E-beam lithography

Low temperature coefficient with no partial discharges

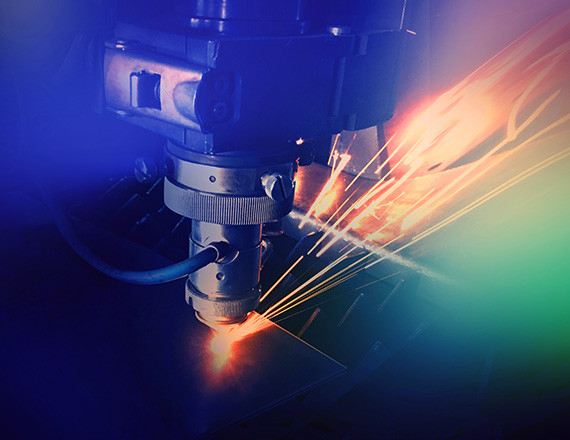

E-beam lithography allows the creation of nanoscale patterns in semiconductor manufacturing and research applications. However, partial discharge and low stability at high voltages impact the performance of e-beam lithography tools which can lead to lost revenue for semiconductor manufacturers.

High stability power supplies prevent yield issues

The stability, precision and performance needed in a power supply

Equipment damage due to short circuit and shielding issues is a problem for design engineers as it affects yield. To deliver the performance needed, e-beam tools require power solutions with high precision and a low temperature coefficient with no partial discharges.

Our integrated and customized solutions provide the high voltage stability, low ripple and short circuit protection you need.

High stability products for e-beam lithography applications

ET Series

Output voltages 0-1kVDC to 0-60k VDC

2U 19" rack mount

Single phase AC input

Efficiency >85%

Low ripple <0.03% RMS of rated voltage at full load

Voltage & current monitor outputs

WJ Series

Output voltages 0-70kVDC to 0-125kVDC

RS232/USB control & monitor standard, Ethernet is optional

Output voltage & current regulated

Air Insulated

CE marked for EMC, low voltage (LVD) & RoHS directives

Operating temperature: -20°C to +40°C

LQ Series

Output voltages 0-1kVDC to 0-12kVDC

Parallelable to 50kW

0 to 100% programmable voltage & current

Low ripple <0.1% RMS of rated voltage at full load

Voltage & current monitor outputs

3 phase 208VAC input standard, 200/380/415/480VAC options